This is the second article in our Building a Shower series and in it we will walk through the process of building a custom shower pan using the traditional technique of a sloped mortar base with a sandwiched vinyl shower liner.

Before you begin building the shower pan, you should have framed shower walls and subfloor with drain plumbing and supply plumbing in place – both of which are covered in our first article How to Build a Shower: Framing and Plumbing.

Shower Pan for Tile: What it is and how to Build One

A shower pan is the sloped base of a walk-in shower that forms the shower floor. The shower pan usually is built around a specialized floor drain which is sealed to the waterproof layer of the shower pan.

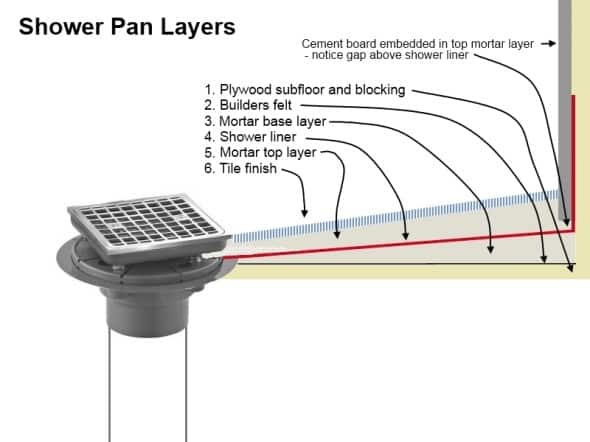

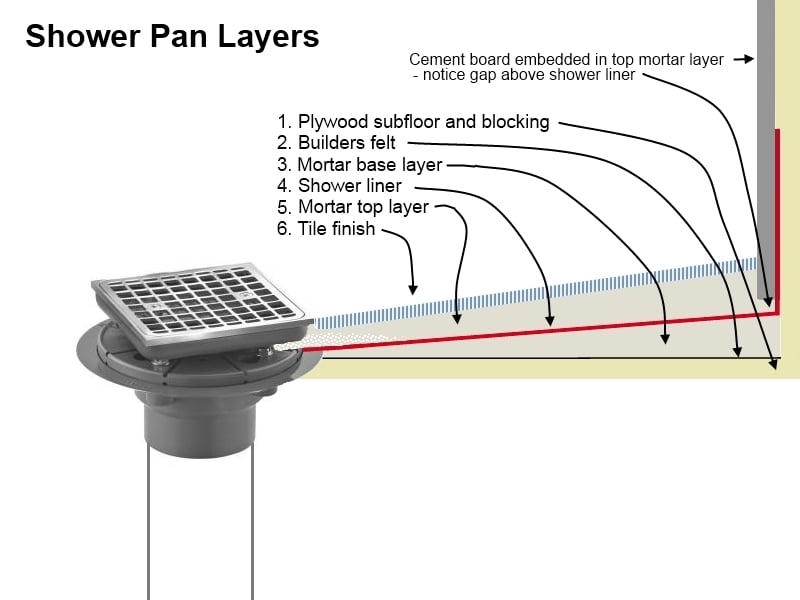

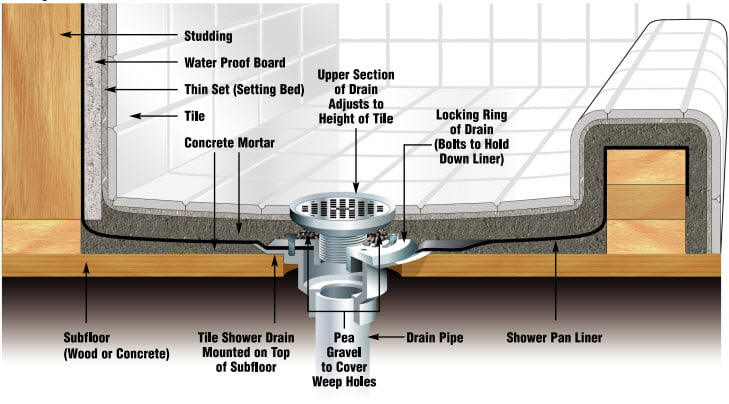

Traditional shower pans where built using dry-pack mortar (concrete) with an embedded waterproof membrane or layer that is sealed to a specialized shower drain that allows water to drain into the main drain opening as well as side weep holes.

The finished shower pan forms the slight-sloped floor of the shower and is often finished with a tile surface. A shower pan is traditionally constructed in two layers with an embedded water-proof membrane or layer in the middle.

This middle layer serves the special purpose of redirecting any shower wastewater that has passed through the surface of the shower floor back into the drain.

The Shower Pan Serves Two Primary Functions

- To quickly direct shower wastewater into the shower drain by way of a sloped-to-the-drain surface.

- To redirect any water that has passed through the shower floor and contained by the water-proof shower liner, back into the side weep holes of the shower drain.

While the sloped surface of a typical shower pan handles a majority of shower wastewater, proper functioning of the water-proof middle barrier or shower liner (#2 above), is crucial for a properly functioning, dry, mold-free, leak-proof shower build. Mortar is water resistant but readily water permeable. Because of this, some water will find it’s way through the shower floor and if this passed water is not stopped, will result in a leaky shower.

So Why Build a Traditional Mortar Shower Pan?

Although there are many ready-made shower pan systems available, it’s hard to beat a traditional hand-made mortar shower pan. Hand-built mortar shower pans are inexpensive, long-lasting and, if done right, reliable and leak-free for decades.

While off-the-shelf pre-made shower pans offer speed and ease of installation, they often lack the rigidity, strength and flexibility of a hand-poured mortar pan. Packaged systems (Kerdi, others) get expensive and complicated without offering compelling advantages over hand made shower pans. But, hand-made mortar shower pans do require a bit of patience and work.

How Do You Build a Mortar Shower Pan? Its All About the Layers…

A hand made shower pan is built in layers around a shower drain assembly.

Shower Pan Layers in Steps:

- Frame the shower walls, install subfloor and shower curb

- Add wall blocking to create shower pan “box”

- Install the shower drain assembly through shower subfloor

- Cover shower subfloor with asphalt saturated felt (tar paper)

- Place the first mortar base layer, sloped from walls and curb to drain base

- Install the shower liner and seal and clamp to the shower drain

- Install tile backer board on shower walls gapped above shower liner

- Place the top mortar layer over the shower liner, sloped from walls and curb to drain

- Finish the top mortar layer – typically with tile

Building a mortar shower pan is a relatively simple task of assembling these layers. It will take a bit of time and some work, but the reward will be a long-lasting, leak-free, durable shower base.

Start With A Strong, Stable Base

A new shower built with a mortar shower pan, concrete backer board and tile is heavy. Before you begin, ensure that you have adequate sub-flooring, framing and appropriate shower drain plumbing in place. More information regarding the prep and finish work of the shower pan can be found in the other shower construction articles:

- How To Build a Shower Article 1 – Shower framing and plumbing

- How To Build a Shower Article 3 – Shower tile installation

If you are ready to build your own shower pan, read on. Prior to starting on the build, you should have a properly framed and plumbed shower rough-in (covered in the first article of this series).

If all of this is in place, get your tools and materials ready to build a shower pan…

OVERVIEW | Build a shower Pan

SUPPLIES LIST | Build a shower Pan

-

Asphalt Felt 15#

TARCO STD15 36x144#15

Much cheaper to purchase locally because of shipping costs.

Asphalt Felt 15#

TARCO STD15 36x144#15

Much cheaper to purchase locally because of shipping costs.

-

PVC Shower Liner Cement

HH-66 PVC Vinyl Cement Glue

Do not use PVC pipe cement!

PVC Shower Liner Cement

HH-66 PVC Vinyl Cement Glue

Do not use PVC pipe cement!

-

Shower Bed Guide

Goof Proof Shower STE-201 and EXT-202 kits

Pre-Pitch guide for first mortar layer and Quick-Pitch guide for top mortar layer

Shower Bed Guide

Goof Proof Shower STE-201 and EXT-202 kits

Pre-Pitch guide for first mortar layer and Quick-Pitch guide for top mortar layer

-

Shower Bed and Curb Guides

Goof Proof SSK-401 kit

pre-pitch, quick-pitch and Kirb-perfect kits

Shower Bed and Curb Guides

Goof Proof SSK-401 kit

pre-pitch, quick-pitch and Kirb-perfect kits

TOOLS LIST | Build a shower Pan

STEPS | Build a shower Pan

- Prepare subfloor and drain plumbing.

Prior to placing mortar for your shower pan build, your subfloor should be flat and suitably strong. I used 3/4″ plywood over reinforce floor joists. You will need to install the lower portion of the shower drain assembly installed (see How to Build a Shower: Framing and Plumbing for shower drain install details)

Before you build your shower pan, you should have a solid subfloor and properly installed drain base.

Stable subfloor base of 3/4″ plywood for shower pan. - Frame the shower curb.

If building a shower curb, you have two main options:

- Use lumber (stacked 2x4s or 2x6s) or blocks as a curb core.

- Use forms to pour a concrete curb.

I used option #1, using 3 stacked 2x4s to form a curb. To do the same, stack and fasten several (I used 3) 2x4s sequentially to the subfloor. First, screw the bottom 2 x 4 to the subfloor, and then screw the second 2 x 4 to the fastened first 2 x 4 and repeat to desired curb height.

Then fasten metal mesh to the lumber curb to help hold mortar to it, which will be applied with the first mortar layer. You may also skip attaching mesh and a first layer of mortar to the curb lumber and simply wrap the shower liner directly over the 2 x 4s, skipping the bottom mortar layer on the curb and just applying a top, final, mortar layer on top of the shower liner.

Stack 2 x 4s to create a curb frame.

Wire mesh secured to wood shower pan curb with staples. Do this to mud over the curb frame prior to laying the shower liner. Optionally, you can install the shower liner directly over the curb lumber and skip the mesh and first layer of mud for the curb. - Form the shower pan box frame with blocking between the studs.

Create the shower pan “box” form by installing blocking between wall framing members. Use framing pieces or sheathing material as blocking. I used scraps of the leftover 3/4″ subfloor plywood. The blocking should be at least as high as the shower curb.

Build a shower curb frame using stacked 2 x 4s. Add blocking between wall studs to form shower pan “box”. - Prepare shower pan for the first mortar layer.

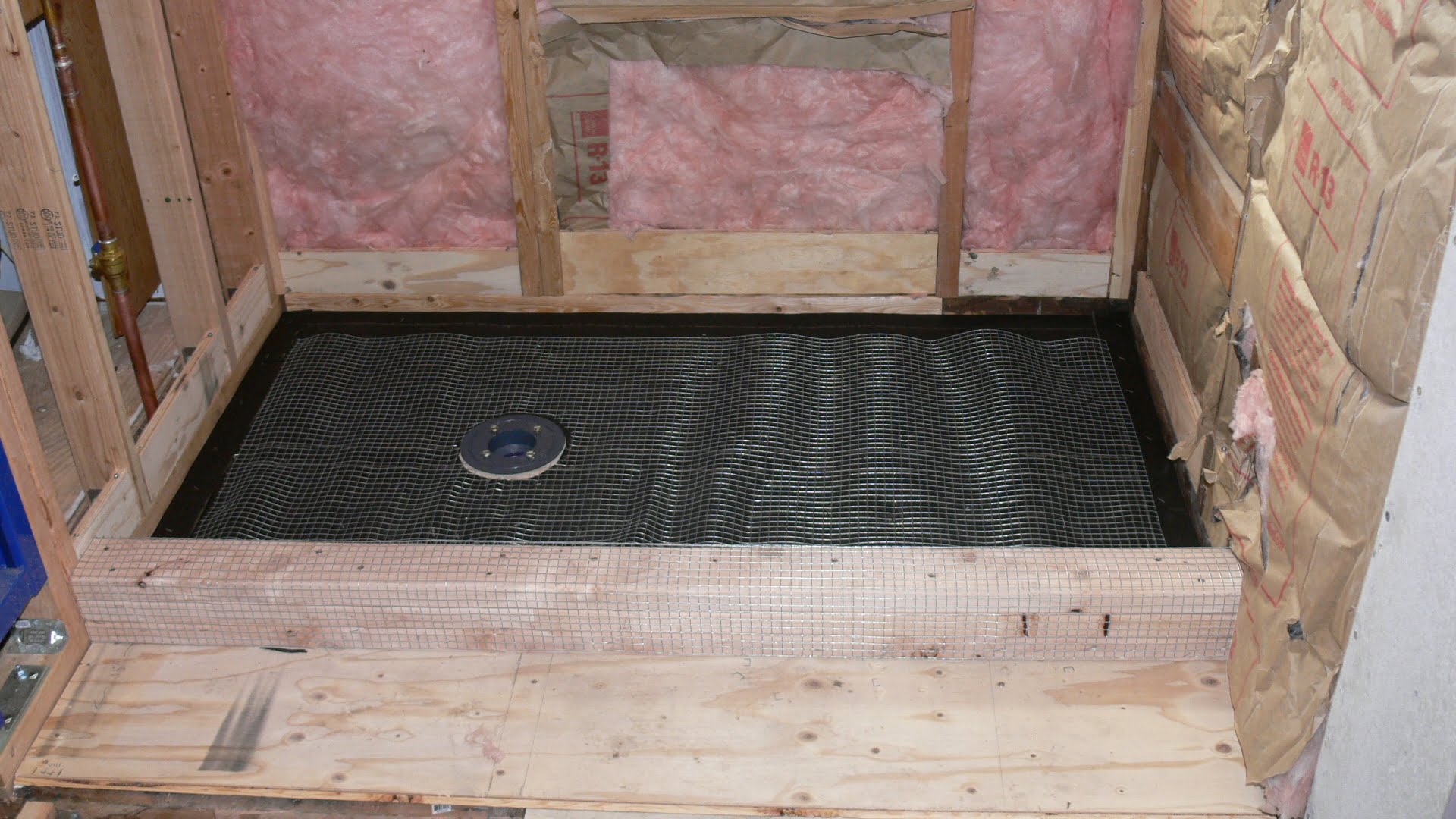

Prepare the bottom of the should pan box for the first mortar layer by installing a layer of asphalt felt over the subfloor plywood. This felt layer will serve as a moisture barrier for the first layer of mud helping the mortar to retain moisture while curing. It will also help to isolate the subfloor from the shower pan. Install the asphalt felt to cover the entire bottom surface of the shower pan, cutting an opening for the drain. Secure with several staples.

Over the asphalt felt, install a layer of mortar reinforcement mesh. Use galvanized hardware cloth (metal mesh) or a plastic or synthetic reinforcement mesh. If using a metal mesh, bend to create slight waves in the material to improve embedding of the mesh within the mortar layer. If using metal mesh, use care to avoid sharp edges above the mortar layer that could damage the to-be-installed shower liner which will lay above the first reinforced mortar layer.

If using a slope guide system like the Goof Proof Pre-Pitch (STD-201) guide, you would typically not use a reinforcement mesh.

Cover subfloor plywood with layer of tar paper.

Add stucco wire or galvanized wire mesh to reinforce the mud mortar. Notice waves in mesh to help embed in mud pour. - Mix and place the first mortar layer.

Traditional floor mix mortar (floor mud, deck mud or dry-pack mortar), which is used to build mortar shower pans, is a 4 – 5 to 1 mixture of sand and Portland cement plus water. When making floor mix mortar, add just enough water to hydrate the mix. Excess water will weaken the mortar. Limit the amount of water by adding just enough water to create a thick, clay-like mixture that just holds its shape when packed. Once packed, you should not be able to squeeze water out of the mix.

A latex concrete admixture can be added to the mortar mix to improve compressive strength, flexibility, durability and adhesion of the mortar mix. Follow the directions of the specific product you plan to use. Generally, latex admixtures are substituted for some of the water in the mix. For my mortar mix, I used a 50:50 mix of water and latex admixture to hydrate the mortar.

To make the mortar, begin by dry-mixing the mortar mix (even if from a premixed bagged product) thoroughly with a hoe to ensure proper sand and cement contact. Next, add water (or a water plus latex admixture blend) using only enough water to create a mix that will hold its shape when squeezed in your hand, but not release excess water. Drier mortar mixes create strong, stable concrete with less shrinkage and higher compression strength.

Dry-pack floor-mix mortar prepared by adding just enough water to hold a ball shape when compressed. With the mortar mixed, place the first mortar layer. Slope the mortar bed with a 1/4″ – 3/8″ slope from the walls to the drain location. Prepare for the slope by marking the walls of your shower with a mortar level that will provide the desired slope to the drain. Calculate the amount of height needed at a wall by multiplying the distance to the wall from the drain in feet by 1/4″. For example, if the is 3 feet from the drain, the wall mortar level should start 3/4″ of an inch above the drain edge level. To draw wall mortar height guides around the shower, measure any point, add the amount of needed rise and use a level to continue that line around the perimeter of the shower.

You can also use a commercial slope guide (like the Goof Proof kits) to help easily create a uniform pitch mortar bed.

With your shower walls marked and/or a slope guide set up, place your mixed mortar into the shower pan and begin forming your base (“pre-slope”) mortar layer. Add mortar to the pan starting at the rear of the shower pan. Use a straight edge or similar to screed the mud from the wall mark to the edge of the drain base and continue adding mud until the entire pan is formed. If using a pitch guide, like the Goof Proof products, the tops of the plastic struts will form the top layer of the mortar bed and serve as screen guides while forming the mortar bed.

Next, add mortar to form the base mortar layer of the curb. If using 2 x 4s as I did, add mortar to the outside surface of the lumber with its’ attached wire mesh and smooth. If using forms, commercial or your own, fill them with mortar and tool smooth.

Allow the shower pan and curb mortar to cure at least overnight.

Base mortar layer (pre layer) pitch guide. - Install the shower liner.

Next, install the shower liner over the base, sloped, mortar layer of the shower pan and the curb. The shower liner is waterproof and will provide a permanent, waterproof barrier for the shower pan that is sealed to the shower drain. It is very important that the shower liner is installed on a properly sloped mortar bed. Un-sloped shower liners will hold water and cause all sorts of moisture-related problems including mold growth. Do not install a shower liner on a flat subfloor or flat base mortar layer!

Installing the shower liner by first measuring and cutting it to the proper size.

Unfold and spread out the shower liner over the shower pan and around the shower curb. Allow the an additional 8 to 12″ of liner at the shower walls to allow you to carry the liner up the walls well above the level of the shower curb. Before cutting the lineer, be sure to thoroughly flatten the liner along the surface and corners of the pan and shower curb. Liners installed without sufficient slack can stretch and fail.

Prior to laying the shower liner on the shower pan, clean the cured mortar surface of the pan to remove any potential abrasive debris that could damage the shower liner. In addition to cleaning the shower pan base, some will add a layer of roofing felt (tar paper) over the mortar shower base to help protect the liner from abrasion of the mortar base.

The liner should be one continuous piece, covering the entire pan, up the walls and over the curb. The liner is the waterproof barrier for the shower pan – think of it as a pool liner that will need to hold the entire volume of water contained with the pan up to the shower curb. Do not leave it too short when running it up the shower walls and don’t cut or penetrate the liner within this “pool” area.

Once you are satisfied with the position and lay of the liner, use a marker to mark the desired cuts on the liner. Do not cut the shower line at the corners or as it passes over the curb. Instead, fold the liner at corners (similar to wrapping a gift) and tuck them into the wall cavity at corners.

If you must cut the liner at the curb or for complex corners, use commercially available patch kits with the proper liner adhesive to cover the cuts.

To accommodate the thickness of the shower liner against the lower walls of the shower, some will shave some material from the face of the lower portion of the shower studs. This step can help ensure the to be installed backer board will lay flat over the area were the shower liner passes up the shower walls.

With the liner marked, remove the liner from the shower and cut the liner using a scissors or similar. Then, place the liner back into the shower to confirm the proper size and fit. Next, smooth the liner over the shower pan and into the corners. Fold the corners and tuck the fold toward the wall cavity or against corner studs if present. Secure the top of the liner and top of the folds with roofing nails or exterior grade screws only the the very top edges of the wall portion of the liner. You may also use liner adhesive or silicone caulk applied to the field of the shower pan for added stability.

It is essential that you do not penetrate the liner below the level of the shower curb as accumulated water can pass through fastener penetrations leading to leaks.

Finally, secure the liner to the to the shower curb using liner adhesive or silicone caulk applied to the shower side and top of the mortar curb. Do not use nails, staples or other penetrating fasteners on the shower side or top of the curb if possible. The top of the shower curb should provide a continuous, waterproof path back to the shower pan and shower drain. Holes made by fasteners along this path will compromise this barrier.

To finish the shower liner over the curb, trim the liner at the front top edge (as I did – see above photo) or fold it over the top edge to the front face of the curb if you may benefit from waterproofing the front face of the curb (if you do not plan to install a shower door or glass for instance).

Shower pan liner install. Carry the liner up the walls 8 – 12″ and avoid penetrating the membrane with fasteners below this level. - Seal the shower liner to the shower drain.

Shower drains are specialized drains with a clamp mechanism used to seal to shower liners. Shower drains also have weep holes in their sides, just above the liner clamp to allow weep water to re-enter the shower drain. This way, any water stopped by the shower liner will flow downhill along the shower liner and back into the shower drain.

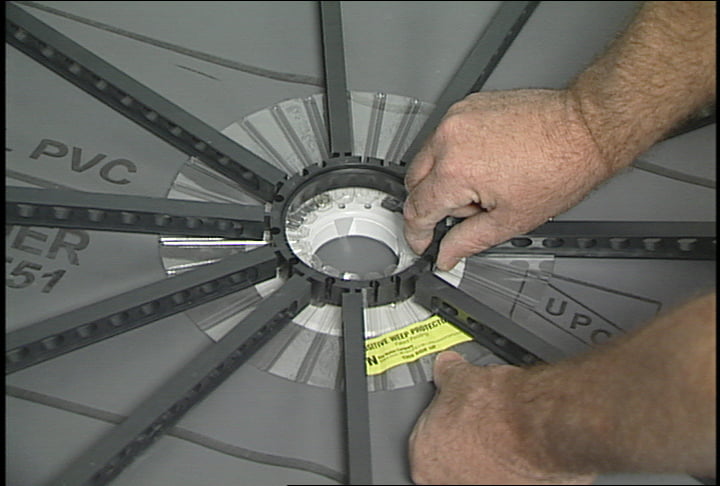

To connect and seal the shower liner to the shower drain clamp, first cut out the portion of the drain liner that lies directly under the shower liner. In addition, make very small slits over the drain base bolts to allow the bolts to pass through the shower liner. Next, run a bead of silicone caulk or specialized shower liner sealant under the cut edge of the shower liner at the cutout for the shower drain. Now install the top drain clamp over the shower liner and tighten the mounting bolts to seal.

Once the shower drain clamp is in place, install the remaining drain riser piece into the drain throat. Most shower drains have thread on both the drain riser and drain throat to allow height adjustment of the drain level. Adjust this level to match your planned mortar thickness and tile thickness of the top shower pan mortar bed.

With the shower drain sealed to the shower liner, you should have a waterproof shower pan which can be flood tested once the sealant used under the liner clamp has cured.

Using sharp knife carefully cut the liner to match the inside contour of the drain hole.

Add silicone sealant below membrane. Do not apply sealant on top of liner.

Install drain clamp and tighten drain bolts to seal with shower liner.

Insert drain riser into the drain throat and adjust drain height to match final concrete layer plus tile height.

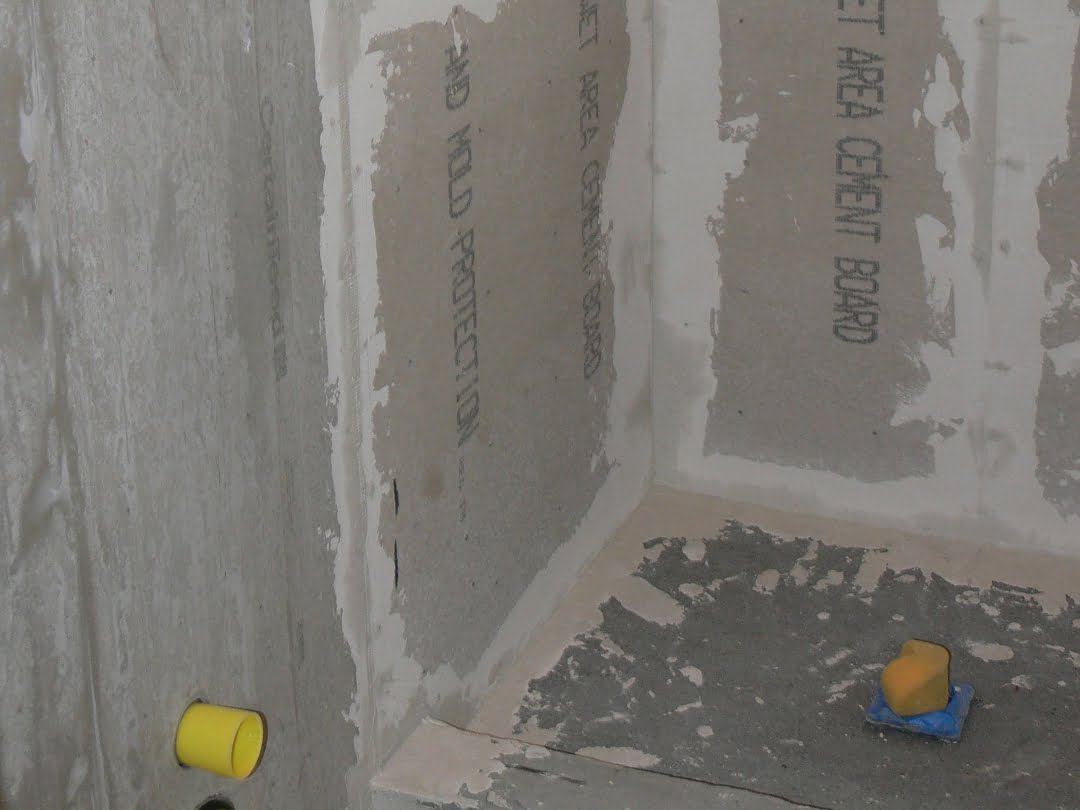

Adjust drain riser to accommodate desired to mortar layer thickeness and planned tile use. - Install the shower wall tile backer board and place the top mortar bed.

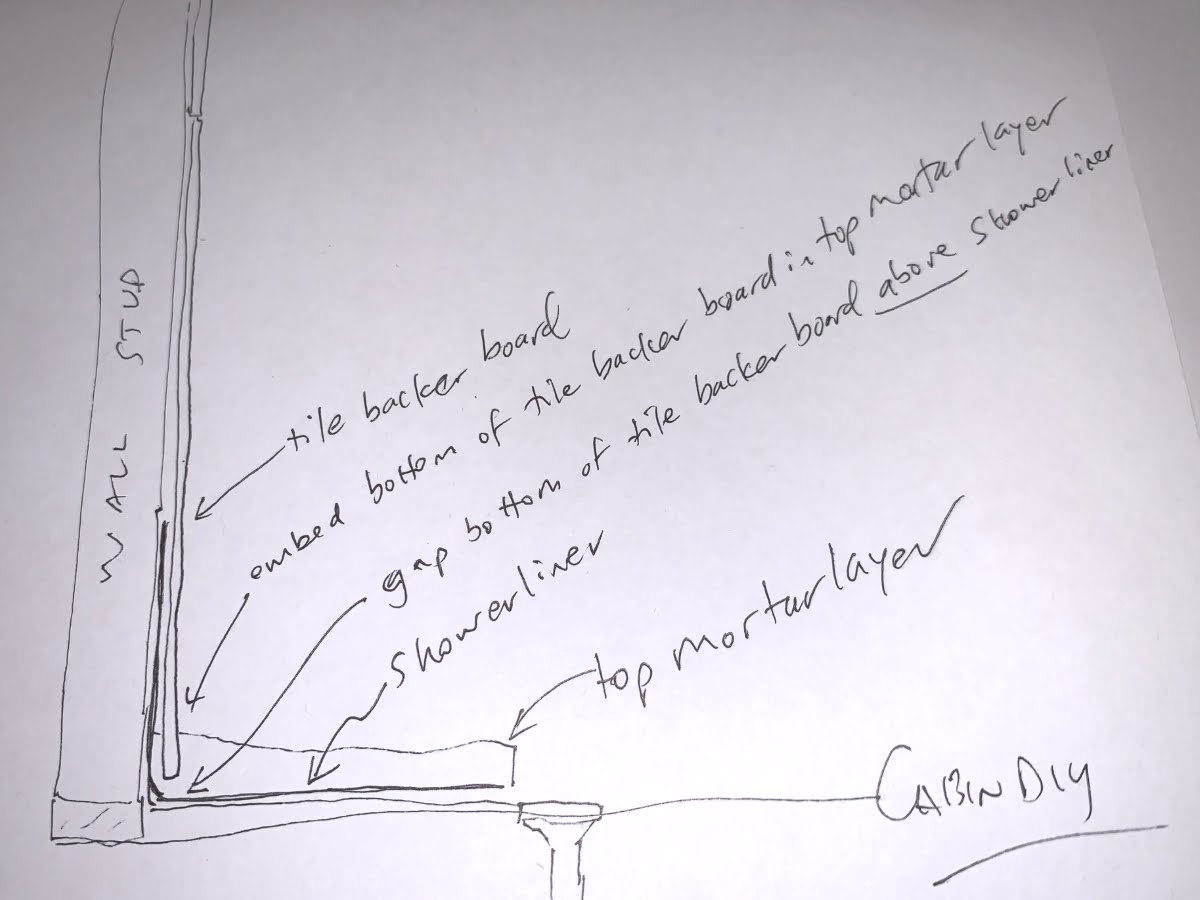

Prior to placing the top mortar layer of the shower pan, install the tile backer board so that it will be embedded into the shower pan top mortar layer. Embedding the tile backer board into the top mortar layer provide structural stability of the shower walls and allows for proper water runoff from the shower walls onto the shower floor.

Install tile backer boards slightly gaped (1/2′ or so) above the shower liner surface. This gap will help prevent mechanical damage to the shower liner from any movement of the tile backer board over time. It will also help prevent capillary-action movement of water up and into the wall assembly. For the same reasons, gap the tile backer board above the shower curb as well.

When securing the lower portion of the backer board, use great care to avoid placing screws or nails through the bottom portion of the backer board that could penetrate the shower liner behind the backer board. When installing the backer board, you only need to install the lower course if you like and can install the upper portions after finishing with the shower pan.

With the lower portion of the tile backer board installed, mix and place the top mortar bed of the shower pan.

This top and final mortar layer of the shower is poured directly on top of the shower liner and will serve as the installation base for the floor tile.

Plan for 2″ – 3″ of mortar for this layer. Slope this top layer the same 1/4″ to 3/8″ per foot as the bottom mortar layer. This top layer of mortar should have sufficient thickness for mechanical integrity and in general, should be at least 1 1/2 – 2″ thick at the drain. Since you have already sloped the base mortar layer which you are placing this mortar layer on top of, this layer can be a uniform thickness, depending on the existing slope of the first layer.

Adjust the height of the drain throat to allow for the desired mortar thickness with consideration for the final thickness of the tile and thin set to be installed. The final height of the tiled shower pan should just match the top edge of the shower drain and account for the desired thickness of your planned tile. If you remove the top drain grate, the level of mortar at the drain will be just below or close to flush with the drain collar.

To ensure proper slope of this top mortar bed, mark the walls as you did for the first mortar layer using a level to determine the proper mortar levels at the walls of the shower.

Once the drain height is set and walls are marked, dump damp floor mix onto the shower liner and screed smooth using wooden or magnesium float. Again, work from the back of the shower to the front. Dump the mud directly on the shower liner and screed with a straight piece of 2×4 lumber, level, magnesium float or straight edge.

Once the mud is in place and at the proper slope and thickness, smooth and finish the surface with a steel finishing trowel.

Next, place the top layer of mud over the shower curb, similar to the shower pan, directly on top of the shower liner. You can reinforce the curb mud layer by embedding an “L” shaped piece of wire mesh into this second mud layer. Use care not to penetrate or damage the shower liner with the wire mesh or tools while building this top layer of the curb.

Finally, finish the curb top surface of the a steel trowel.

You are now ready to finish the shower pan with tile. Before tiling, allow the completed shower pan and curb to cure for a day or two. See how to tile your shower here.

Applying the second (top) layer of mortar to the shower pan. Notice installed cement board is embedded into this layer, but be sure to gap it above the shower liner by at least 1/2″.

Completed shower pain and drain with installed and taped cement board.

Completed shower pan after mortar cured and cement board installed. Notice pan height at drain to accommodate tile install.

Before embedding the backer board, should it be Redadgarded down to the bottom edge or should the Redgard be applied after the top mud deck is dry? I’m building a bench and a niche and feel using Regard , reinforced at the transition points, would provide the best option. I’m leary about using a topical floor so I’m planning on using a PVC liner. My concern is wicking at the wall to floor transition.

Hi Shawn,

The order of install from mud to shower liner and Redgard should be:

1. First mud layer of shower pan (the first layer, sloped to the drain)

2. PVC shower liner installed over the cured first shower pan mud layer and run up 1′ or so up the walls and over the curb.

3. Wall backer board installed (no fasteners through bottom portion of backer board that could puncture the shower liner. Some leave a gap between the bottom edge of the backer board and the top of the finished shower pan (idea is to avoid water wicking), and some will embed the bottom of the backer board in the top mud layer of the shower pan to help stabilize the backer board. If you embed the bottom edge of the backer board into the top mud layer, be sure to gap the bottom edge of the backer board above the shower liner to avoid mechanical damage to the shower liner.

4. Top (final) mud layer of the shower pan placed over the installed shower liner.

5. Paint-on waterproofing membrane (Redgard) application to walls and cured top pan mud layer (sealing the top surface of the shower pan may impede the drainage of water through the top mortar layer of the shower pan. Water which has passed through the surface tile or grout lines is supposed to move through the top shower pan layer and follow the shower liner which is sandwiched between the top and bottom shower pan mud layers, into the side weep holes of the shower drain.)

Gary

Fabulous tutorial! Thank you for this. Question for you- Just starting the planning of my shower remodel. I live in Florida and have a cement subfloor. I am planning on using bricks for my curb. How would I attached the wire mesh to the curb and subfloor?

Thanks!

Jennifer

Hi, great article! Specially because we are just about to build our own shower pan. A couple of questions if you don’t mind:

1) I was wondering what should be the minimum thickness of each mortar bed?

2) I was reading the instructions of the mud bed I intend to use and it mentions to put the wire mesh in the middle of the mortar layer. Is there a difference between putting it in the middle or under? What would be the best way?

3) For the curb, would it be fine for me to cover the wood with beckerboard instead of using the mesh and mortar?

Thanks!

Talita

Hi Talita,

Thanks for using our site. Your questions:

The liner is then laid over this cured first layer and sealed to the drain clamp. The second layer is poured (placed) on top of the installed shower liner. This top layer is typically thicker to provide strength as this is the layer that will be tiled and the finished floor layer of your shower pan. Most make this layer at least 1″ thick at the drain and again slight slope so the layer is thicker at the walls. It is true that if you sloped the first layer, all you need is a uniform layer of mortar at this top layer, as the slope will mimic the first sloped layer. I think my top mortar layer was 1 1/2″ or so at the drain and 1 3/4″ or so at the walls.

As you see in my images, I did use a wire mesh on the bottom mortar layer, but if you do, make sure the mortar fully covers it. Many place a wire mesh reinforcement layer in the top mortar layer too.

OK, good luck and have fun! Let me know if there is anything else,

Gary

How many days working how many hours per day does it take for one person to build the Shower bathroom floor. Including letting the cement dry, shower pain, and tiling of shower floor. Not including entire buildout of a whole bathroom. Just the shower part?

Hi Tim,

I would say 3 to 4 days of several hours per day. Most of the delay is allowing the two mortar mud layers to cure (each overnight). If you can pour a mortar layer on days 1 and 2, you should be able to start tiling on day 3. Here is a summary of the rough steps to building a shower pan (floor):

Day 1: Plywood sheeting over joists (if not already in place). Cut and install drain base. Blocking of stud cavities. Build curb (if using wood). Asphalt felt over plywood base. Stucco wire (if using). Pour and slope first (base) mortar mud layer. Allow mortar to cure overnight.

Day 2: Install shower liner over cured base mud layer and over curb and run up walls to a level safely higher than the curb (12″ or so). Cut out shower liner and install drain clamp and drain riser. Install tile backer board on shower walls (at least the lower course to allow the lower edge of the wall tile backer board to be embedded in the top shower pan mortar layer). Pour and slope second mud layer over shower liner and curb. Allow mortar to cure overnight.

Day 3: Tile shower pan (floor) and walls.

So my question is,

New house construction, master shower is on concrete, first layer of slop was installed then a fiberglass mesh and luquid was formed to create the shower pan. it looks like the fiberglass used to build boats. there are what looks like staples sticking into the shower from the outside through the fiber glass. what are these for as they are uniform in placement? i was going clip them off, install the lower portion of backer board and put three coats of redguard on the walls before tiling.

Hi Kathy,

Thanks for the question. Yes, fiberglass can be and is used to create shower pans. And, yes, marine fiberglass resin is often used as it is water-resistant and tends to be flexible and not crack with structural movements of your home. I would guess the staples were used to secure the fiberglass mesh prior to applying the resin. I think you plan is sound, but I would flood test the shower pan prior to moving forward to ensure the fiberglass pan is still functional.

Gary

It says to embed the concrete board into the mortar then it also says to leave a half inch gap between bottom of board and top of pan liner. I don’t understand exactly what is meant by that. My thinking is that the pan liner extend up the studs 4 to 6″ above the top of the actual shower pan. so if I leave a gap, how do I embed the bottom edge of the concrete board? I hope my question makes sense! Thanks for your help!

Hi Jen,

Thanks for the question and sorry it wasn’t more clear.

The bottom edge of the tile backer board is gapped above the horizontal portion of the shower liner. This helps avoid mechanical damage to the shower liner from the bottom edge of the tile backer board. This bottom-gapped sheet of backer board is fastened with roofing nails or backerboard screws to the wall studs starting above the height of the shower liner travels up the shower walls. Once the backer board is installed, place your top mortar layer, embedding the bottom of the backer board within this top mortar pour.

Here is a quick diagram of the tile backer board gapped above the shower liner and embedded in the top mortar layer:

What would you recommend I use for the final top cover of the shower pan (on top of the mortar bed) if I am not going to tile it? We just want a cement-like surface

Hi Reldon,

Interesting question. You could just “finish” the top surface of the top mortar bed. I would probably modify the top mortar bed to include some small aggregate like pea gravel or similar and add latex and for sure some embed some type of reinforcement wire or mesh within the mixture. Straight mortar (Portland cement and sand) makes a good tile base but would not be very durable. Adding wire and aggregate should add strength and durability.

I would also make a rich (more Portland cement) mix that should be like a stiff concrete mix instead of a dry pack mortar. A more concrete-like consistency will be easier to trowel smooth, but remember that less water = more compressive strength, so keep the mix fairly dry (thick paste-like).

Once the concrete has cured, I would hone or polish the surface and seal it with a clear finish or sealer. You could also consider a concrete paint or garage epoxy finish product. Obviously, any smooth surface created using these products could create slip hazards within the shower and you may want to add grit to the concrete mix or finish. I would think carefully about the grit choice as you would want the right mix of anti-slip, foot-feel, wet durability and look. Micronized polypropylene might work. I am certainly not a concrete expert, so it may make sense to consult someone with more experience with concrete finishes.

Of course, you could just add tile and be done! Good luck and let us know how it goes. Sorry for the slow response, I’m traveling currently.

Gary

Great article. Thanks for sharing.

I am at the stage where I applying floor mud to the curb, on top of the liner.

I’m working with a neo-angle, so there are some odd folds etc. to the liner. Because of this, in some spots, the liner does not sit flat against the curb (I guess you could say their is almost a “bubble” under the liner).

I am worried that even with mesh, my mud layer is going to be unstable because the liner does not sit nicely flat against the curb. I would staple or otherwise affix it, but that would put holes in the liner!

Any suggestions? Only think I can think of is using something like the Kirb-Perfect to stabilize the top mud layer – but I can’t find anywhere that sells it where I am (SW Ontario)

Hi JM,

Thanks for the question. My initial ideas are:

Gary

my tub has a 11/2 drain. when converting to shower would it be adequate size. wall enclosing drain make it impossible to change piping unless I tear complete wall out.

I have a want to build a shower from scratch. Removed the old tub and moved everything, including plumbing to a corner of the bathroom. I want to install tile of the walls and floor. I understand all that you are stating, BUT I have an elderly mother that will be in a wheel chair very soon. Need to build a rolling shower. The house has a crawlspace and not a basement. I guess I need assistance on building a shower pan box that is recessed. I have been researching for some time and getting a lot of information, BUT I still haven’t found how deep I can build the pan box and about what is the approximate depth of the first application of Mortar?

Also, you stating that it is dry mortar – SO just add enough water to make the mortar moist and pack it down?

Thank you very much in advance of your help.

Hi Bill,

Thanks for the questions and sharing your project. Let me do some searching for resources regarding building a curbless shower. Yes, the shower pan mortar is dry pack – add just enough moisture to activate the cement. You should be able to form a ball with the mortar that holds its shape but doesn’t release water when squeezed.

Is this the type of shower you are looking to build: Accessible shower build on Houzz

Ok thank you

Here is another pic here the cement moves

Hi Kenny,

Thanks for the question. The prepitch first mortar layer is the base layer that provides slope for the liner. As long as this layer is structurally sound, a few cracks should not matter. To me the mortar looks solid and I would proceed with the liner install followed by the top mortar layer.

Gary

Hi i just build the pre picth mortar but it crack in some places do i need be concern or dont worry since i will installing a liner?

My question is about the drain its self. My plumber installed the oatey grey shower flange. It has 1/8 bevel on the flange where it meets the floor. He beveled the subfloor so it is level with the top of subfloor and screwed down. My question is how will this effect the preslope bed where it meets the flange since it is flush. they way i understand your instructions the slope should be 1/4 inch tall at the flange.

Hi Jason,

Thanks for the question. You are correct. The drain is designed to sit above the shower pan base to allow for the preslope mortar. I suspect he doesn’t build a preslope mortar layer in his shower pans. Skipping the preslope mortar layer is a big mistake as the shower liner will not be sloped to the drain but just flat on the shower pan base (subfloor). A non-sloped shower liner will tend to accumulate water within the shower pan potentially leading to leaks, organic matter growth, odors, etc., etc.

I would have this corrected and consider using another plumber. Here is a very good image showing the Oatey shower drain install:

(Diagram of Oatey adjustable shower drain and shower liner install. Source: Oatey.com)

Gary

Hi Gary,

It’s been a little while since I last visited, but I get your emails from the website when people post. Nonetheless, I wanted to offer a great solution for many who are concerned of any wire reinforcing puncturing the liner. I really try to stay away from using any plastics nowadays, but for some applications it’s a great solution. I use plastic wire mesh (sold in the box stores) for my mortar preslope and for the reinforcing in my actual shower pan float. If I don’t use the plastic wire I would always put tape over any exposed sharp edges of my cut galvanized chicken wire. I will tell you though, I just removed a bad pan failure (someone else’s) and found that over three years or so the galvanized diamond lath had completely turned to dust by the drain where the leak was.

Hope this helps!

Onga

Hi Onga!

It’s been a while, thanks for visiting!

Good advice as always. I only use metal mesh in the bottom mortar layer and not in the top layer. Plastic mesh would be a great alternative for the top mortar layer to help avoid damage to the shower liner.

Hope all is well!

Gary

Is there a video you can recommend? I like your very detailed descriptions. I’m attempting to correct a mistake a contractor has made. He build a shower where water accumulates on the side rather then going into the drain. It drains into my hallway. Now I have a difficult time trusting anyone to do it correctly. Any tips?

Hi Is,

Sorry to hear about your shower troubles. I sounds like the shower pan is not sloped properly to allow water to drain into the shower drain. If the shower pan was not sloped properly, it is very possible other steps where not completed correctly during the shower pan build.

Here is a good general overview of a traditional shower pan build using a shower liner and two piece drain: Shower pan build video

Thanks for using our site and thanks for the question.

Gary

I was noticing that there is conflicting information with regards to the ordering of the installation of the backer board and the top mortar layer. In some places it says to install the backerboard first and the add the top layer of mud; in other places (including the pictures, and the list of steps), it shows putting in the top layer of mud first, and then the backerboard. I guess either is OK?

Hi John,

Sorry for the confusion. When using a traditional shower liner membrane (as in this article), the tile backer board should be installed over (after) the shower liner is installed to provide the proper layering and water protection.

Because a traditional shower pan is created in two layers with a sandwiched shower liner membrane, the first (base layer) of mud is typically placed first, followed by the shower liner which covers this base layer and is carried up the shower walls and then the tile backer board is installed over the shower liner. Finally, the top mud layer is placed.

Other, commercial shower pan and water-proofing systems may allow for backboard install prior to pan install. With a traditional mud shower pan, backer board install follows the liner install. As long as the backer board is installed over the shower liner, your shower should perform well. Embedding the backerboard in the top layer of mud is not necessary, but likely improves the stability of the installed backer board.

Gary

Thanks for response. Indeed I wasn’t wondering about the possibility of installing backerboard *before* the liner (which sounds quite bad); instead just about the whether the backerboard is tucked down into the top mortar layer (as shown in th diagram) or not. My feeling is that’s not a good setup, because backerboard I believe does wick water, and that means it will be wicking water up the wall. Instead (after thinking and reading about it some more) there should be an “air gap” (or caulk gap, as the case may be) between the top tile layer and the backerboard, to prevent such wicking. I ended up doing that, at least. In my case I have large tiles for the walls, so there’s no concern for stability. If I was doing small tile for the walls then stability might be more concern, and I’d perhaps be inclined to do as the diagram shows. In that case though I’d probably do something not shown in the diagram – whichis to apply some waterproofing on the backer (e.g. redgard) before laying the top mortar layer, to prevent wicking up the wall.

Hey John,

You bring up an interesting point concerning potential water wicking. I would guess the significance of any water wicking up into the backerboard would depend on the presence and height of the shower liner behind the backerboard. A properly installed shower liner running up the lower portions of the shower walls should contain moisture carried into the lower portions of the backerboard. It is true that the additional moisture carried into the backerboard may dry into the wall cavity and potentially lead to problems over time.

This isssue may support the practice of waterproofing the front of the backer board (at least the lower portions that will see a majority of the water from shower use) to help prevent water passing into the backerboard by way of grout lines.

Probably the take home message is to carry the shower liner well up the wall behind the backer board. I would also consider a paint-on waterproofing agent – especially over the lower portion of the shower walls. Your idea to gap the bottom of the backer board makes sense too, with the trade off of what ever structural benefit that is gained from embedding the backer board. Interesting…

Gary

Question regarding using *both* an isolation layer (the tar paper or plastic under the bottom mortar layer) plus the shower pan liner. Won’t this form a “mold sandwich”, such that any moisture that gets between the two (either moisture from the air, or any leaks that happen to happen) ends up staying around? It seems like you’d want to have just a single waterproof layer (the main liner) and not two. Is that not the case?

I’ve seen this point made, for instance, with people who are doing the side walls of the shower and propose to use both tar paper (under the cement board) and red gard (over the cement board). The general consensus I believe is that’s a no-no, because of the “mold sandwich” effect of having two waterproof layers. Is that not the case with the shower floor as well?

Thanks for doing this tutorial. It’s like my bible for rebuilding a moldy shower.

I didn’t want to buy a whole role of tar paper for a little 3×5 space. Is 4 mil plastic enough of a vapor barrier between the subfloor and initial layer of mortar? What is the benefit of tar paper over another vapor barrier?

Thanks again,

Brad

Hi Brad,

My understanding of the tar paper isolation layer main function is to separate the subfloor from the shower pan. A secondary function is to retain water in the shower pan mud while it is curing to help it cure completely and gain full compressive strength. Therefore, using plastic sheeting should work just fine.

This is a continuation of my above post from Chris.

Before adding the 2nd mud layer, I coated the bottom 3″ of Hardie Backerboard with Redguard to prevent water weeping into the Backerboard.

In one of your answers, you said that some people put tar paper over the liner to prevent the 2nd mud layer from damaging the liner. Oatey does NOT recommend having tar paper (a petroleum product) contact their PVC liners.

I could not find a 135 degree external curb piece for patching the liner and my built in shower seat created two 135 degree external corners. I filled the need by cutting a slit in a 90 degree external corner and then overlapping and gluing the overlapped edges, thus increasing the angle to 135 degrees. I then glued this 135 degree curb piece on the inside to the liner and glued additional patches to the outside of the liner for extra safety.

For the shower curb, I did not apply the 1st mud layer since the 2nd mud layer would be structurally independent of the 1st mud layer (separated by liner). Instead of the 1st mud layer, I nailed a 5/8 to 1/2 inch thick (sloped) by 3.5 inch piece of wood on the top of the three 2×4’s. This gave me the extra height and slope that the 1st mud layer would have been provided. It was easier for me to work in wood than mortar and the result was stronger. I then bent 1/2 galavanized hardware cloth and placed it over the three sides of the curb. I nailed the mesh to the curb only on the outside. To make sure that the mesh did not contact the liner, I tied small strips of 1/4 inch Hardie backerboard to the inside of the wire mesh. I then screwed 1/2 inch Hardie backerboard to the outside of the curb to give a perfectly flat outside curb and a sharp 90 degree top outer edge. I then applied a mud layer to the top and inside curb. I used boards to keep the inside curb vertical until the mud set up.

After a few days, I applied the 2nd mud layer to the shower pan floor. For the 2nd mud layer, I put down about an inch of mud, then placed 1/2 inch galanized hardware cloth mesh on top, and the added the balance of mud for the 2nd mud layer. This may be unnecessary but the wire cloth adds a great deal of strength. Care must be taken to prevent the wire mesh from puncturing the liner.

Hi Gary

I went back to review. You complete the wall first and do the floor last. I did the opposite and placed the base of the wall tile on top of the floor. This seemed better from a water run-off standpoint.

Your way, however, eliminates the issue with the line where the wall meets the base not being as precise and seems to make for a neater line.

Have I got that right?

Thanks,

Chris

Gary

I wanted to take a moment to thank you for this excellent instructional. I have rehabbed two bathrooms in my home and am about to start a third and a fourth. The second one had a custom shower pan and I was very frustrated with the contractor who did the work. He apparently doesn’t own a framing square. “Can’t see it from my house” was his attitude which is the reason I do so much of my own work. (plus I love the work). The glass guy’s first comment was, “That pan isn’t square!” but he was able to work around it. Finished product is fine (only I know it isn’t square) but now I have the confidence to do it myself. Thanks very much.

One question on the tile work. You suggest starting a good bit from the bottom for the walls, I assume to allow for the pitch of the floor. How much of a tile do you allow for the last course? On my job the drain was in the center so all the walls started at the same height and I used tile with a flared base at the same height all around. The new job will have the drain at one end. The bottom tiles, then, are not a full height and each is tapered according to the pitch of the floor?

Thanks again.

Regards,

Chris (Mistrfix)

I see you put wire mesh in the bottom layer of morter to add strength then lay the membrane but it doesn’t show putting an type of mesh or reinforcement in the top layer?

Don’t you need this to prevent it from cracking?

Thanks for your very detailed description on ow to make a shower pan.

I am building an elongated neo-angle shower with a bench in the corner. I have attached a couple of pictures of the framing that I am now in the process of building. After I install the first layer of mud and the liner one foot up the wall, I will bring Hardie backer board down to 1/2″ to 1″ above the liner. I will also cover the bench with Hardie backer board. I am concerned about installing the liner over the irregular shape. Do I need to cover the entire bench with the liner? Would this have to be done with just one liner piece? I do not know how to secure the liner over the bench without putting nail or screws holes through it. Or after taping the joints of the Hardie backer boards covering the bench, could I just coat the Hardie board covered bench with a few coats of Red-Guard?

Thanks for your help. Chris

Hi Chris,

Thanks for visiting the site and thanks for your question.

If using a shower liner for the pan of the shower, I would just carry it up the front of the bench and pull any excess material or folds behind the face of the front of the bench. Don’t forget to slightly slope your bench top toward the center of the shower to allow for water drainage from the bench seat. Obviously you will need a few vertical framing members to support the bench and wrap the shower liner around.

Once the framing is complete, use roofing nails or screws to hold up the topmost portion of the liner. Once the liner is mounted, install tile backer board over the liner and over the seat of the bench. The shower pan liner does not typically cover the shower seat, although you could do this – just don’t penetrate the liner anywhere below the seat if you do. If the shower liner only covers a portion of the front of the bench, consider notching the front of the framing to allow the tile backer to lay flat against the framing (same goes for the shower wall framing).

As you suggested, you should allow a 1/2″ or so gap under the bottom of the tile backer to protect the shower liner and avoid mechanical damage to the liner. Next, pour your top shower pan mud layer – which will embed the shower liner in the shower pan mud layer.

Then, to waterproof the shower bench, use a paint-on waterproofing membrane (like Redgard) to cover the seat, any alcove, and all of the tile backer if you like (I covered my entire shower with paint-on membrane prior to tiling). Consider adding membrane reinforcement at the front and back corner of the bench during the paint-on membrane application. Once the paint-on waterproofing membrane is dry, tile over the walls and bench (or add a piece of solid stone for the bench top if you please) using an appropriate fortified thinset/mastic.

Good luck, and feel free to upload progress photos as you go!

Gary

Hi Gary.

I recently followed your tutorial here to create a shower pan, however I have a concern. When my husband installed the faucet he ran quite a bit of water in the shower pan (which had previously been dry for over a week) and now the shower pan is still wet. I could hear the water drain through the weep holes when it was running, but the moisture is concerning to me. It’s now 4 days later and still appears damp. Any ideas of what’s going on here/how to fix it?

I appreciate any insight you may have.

Thanks!

Jen

Gary, The knowledge you share REALLY saves us. Big Thanks and a Big handshake to you, that you TAKE THE TIME to help us with Correct information! My question is in the shower, tile on walls to ceiling. Decided to paint shower ceiling. Should I put a skim coat of thinset before paint? Also, latex or oil base? Thank you, again for your time and help. Rick-O-Matic

Hi Gary,

As most have mentioned here you have one of the most comprehensive tutorials on the web so thank you for that!

I didn’t see this answered in previous comments so hopefully I’m not being repetitive: do you use the same mix for both morter beds? For the base you were pretty explicit about the mix needed but I’m not sure about the one poured over the liner.

Thank you again for what you’ve done here. So helpful!!

Jen

Hi Jen,

Yes, same floor mix mortar for both the below and above liner beds.

G

Can i put the first layer of morter mix ontop of the backer board i already have on the floor? Underneath that is plywood. Would it hurt to just start on top of it like it were the plywood. Or would that cause an issue? Thanks so much

Thank you so much for the tutorial! I built the pan and am now ready for tile.

When I put the liner in I did not do a flood test. I am wondering if there is a way to do a flood test at this stage. I just tried but realized that it will not work because of the weep holes. I hear the water moving into the drain so it appears I have well functioning weep holes! I had my inspection the other day and told the gentleman I would do a flood test. Any thoughts on how to go about it?

Hi Elmer,

You could use an inflatable drain plug that would be easy to position below the drain. You may need to check with your local inspector to ensure testing after your mortar bed is installed is acceptable.

Gary

Thanks so much for the tutorial.

I laid my first layer of cement recently and have a problem. My pan is crumbly and somewhat sandy. Portions of it seem solid, but there are spots that have crumbled away with minimal coaxing. It seems I might have not gotten the mix wet enough or not compressed it enough. I have attached a picture that shows what it looks like after brushing and vacuuming off.

I’m thinking I could fix this with some sort of thinset.

Would that be a reasonable way to fix it?

Hi Elmer,

Thanks for the question and photo. I would guess maybe the mortar mixture was not as well mixed as it could have been (some sand not coated with Portland cement maybe) and mixed a bit dry. Obviously the best fix would be to bust it up and start over, but if most of it is stable and solid, you could likely get away with removing anything loose and patching it with additional mortar mixed with latex admixture instead of water. Latex concrete admixture is available at tile and home improvement stores and when added to mortar will increase adhesion, flexibility and strength. I would mix this mortar a bit wetter so the end mix is the consistency of thick peanut butter.

As you suggested, you could also try a latex fortified thinset. No matter the mortar used to patch, I would paint the areas to be patched with the latex admixture straight out of the bottle prior to patching, this will likely improve the adhesion of the patch.

When considering whether to patch or replace, consider the job of your shower base. It will need to withstand daily use with temperature changes, foot traffic and likely some movement from you buildings forces. If you have any questions of it’s soundness, bust it out and do it right. If you do start over, I would suggest adding latex admixture to your mortar – maybe substituting 50% or more of the needed water with latex. And remember to thoroughly mix the dry components prior to adding liquid – you want each sand particle coated with cement prior to adding water.

Good luck and let us know what you do!

Thanks,

gary

Thanks for your reply Gary

I think I will try the patching method. I will use more admixture this time around, last time I used it for maybe 1/4 of my moisture needs. I will also brush up on my mixing process! Thanks. I will let you know how it goes.

Hi,

I am currently having work done on 2 shower pans. After coming across your site I now have questions for my contractor. My first bathroom has been completed but I now understand that a shower pan lining was not used. He has assured me that by using quikrete hydraulic water stop cement that I will not have issues. He mentioned he did his home this way 10 years ago and has had no water issue. Is it possible to not have water problems when not using the shower pan lining? Im concerned about my showers as the second one is now in progress. I’d like any feedback you have. Thanks.

Hi Aman,

With one very limited exception (see below), every residential shower pan must have a waterproof lining system – either a waterproof membrane embedded in the mortar pan (vinyl shower liner, hot mopping, copper or lead, etc.) or a topical waterproofing system (Kerdi system, paint-on membranes). Section P2709 of residential building code addresses shower receptors (shower pans) and P2709.2 specifically addresses Shower Receptor Liner requirements:

P2709.2 Lining required. The adjoining walls and floor framing enclosing on-site built-up shower receptors shall be lined with sheet lead, copper or a plastic liner material that complies with ASTM D 4068 or ASTM D 4551. The lining material shall extend not less than 3 inches (76 mm) beyond or around the rough jambs and not less than 3 inches (76 mm) above finished thresholds. Hot mopping shall be permitted in accordance with Section P2709.2.3. The completed liner shall be tested in accordance with Section P2503.6.

There was a recent change to P2709.2 liner requirements that applies only to a very specifically designed concrete shower build that is incorporated into a concrete floor. The recent building code changes also require flood testing of all shower pans.

I would be very concerned by the proposed lack of a shower liner or topical waterproofing system. The proposed build by your contractor is likely not code complaint and a set up for future water problems.

Gary

Hello,

Thank you so much for providing this invaluable public service!

My contractor installed fiber cement board on the floor of the shower area, and was planning to tile right over that, with no slope, no waterproofing, nothing. I was lucky enough to see this tutorial in time, and stopped him from tiling, and now I’m going to try to ask him to follow these instructions. Do you think it’s necessary to ask him to remove the fiber cement board, or can we just proceed as you would over plywood, with a layer of asphalt felt, wire, then the topping mix, etc.?

Thanks again.

-Joan

P.S. I neglected to mention that I’ve already had a plumber install the bottom half of the drain, with the fiber cement board in place. So that may complicate matters. I wish I had thought to ask this earlier…I guess I was just hoping it would be okay to proceed as-is. Please let me know what you think. Thank you! -Joan

Joan,

You will need the base of the shower drain installed prior to building the shower pan, so no problem.

Feel free to attach some photos if you like.

G

CDIY

Hi Joan,

There is no problem using cement board or similar as the base layer for your shower pan.

As you point out, it would be a huge mistake to proceed without a properly built shower pan – one constructed without a sloped shower liner.

You can also reference this excellent article for proper shower pan construction:

Shower pan construction br the floor elf

Be careful and have it done right or your shower will leak.

G

CDIY

Great info here. Given me reason to pause my project and consider next moves.

Straight off the top, I’ve made some mistakes that I don’t think I can go back on. I installed 1/2″ backer board directly to the studs prior to liner installation, then poured a curb directly against that backer board. So many mistakes. Really hoping I don’t have to demo the curb and pull the backer board.

The question then becomes: can I pour a pre-slope up against the installed backer board, lay down multiple coats of Redguard on the entire pre-slope and walls up to the ceiling to create a waterproof membrane, then pour final slope, then tile, or is that too risky from a waterproofing standpoint? Redguard ‘supposedly’ meets the same standards as rubber/vinyl, but is this inner-liner idea an acceptable method? Better question is: would it pass inspection?

Also, what is the recommended minimum & maximum thickness of the pre-slope at the top edge of the drain base? Clearly the thicker it is, the higher up the walls the outer rim of the pre-slope will end up, which will also increase the curb height requirements.

Regards

Adam

Hi Adam,

Thanks for the nice words and thanks for sharing your project with us.

Regarding your shower build so far, I think you have a few options. You could do exactly as you suggest and use a paint-on membrane product to waterproof your shower pan and lower portion of the walls. If you do go this route, I would recommend several layers of the paint-on membrane and consider using anti-fracture reinforcement tape for waterproof membranes. If go this route of the paint-on membrane, I would recommend painting the walls as well – I like the idea of carrying up the moisture barrier all the way up the walls, and make sure you cover any coves or cutouts in the shower walls. Also, check to insure the drain you are using will work with paint on membranes – remember most drains are designed to clamp to a vinyl membrane.

Another option is to cut and remove a lower portion (say 2 feet or so) of the tile backer board and then install a traditional shower liner and then reinstall the cut out backer board. Because you have already embedded the backer board in the first mortar bed, in addition to cutting the board a the height you want to remove, you will also need to cut it out of the first mortar bed. You could do this using a flush cut style saw (protect against silica dust – use a mask and vacuum as you saw) or by thoroughly scoring and smoothing any proud backer board above the mortar layer. This surface must be smooth prior to installing the shower liner to prevent damaging the liner.

Once the backer board is removed, install a tradtional shower liner. Remember not to use any fasteners in the lower portion (at least the height of the curb, but ideally a bit higher like 6 – 8″ or so) that would penetrate the liner and allow water to pass through the liner. Prior to installing the liner, consider notching out the front of the studs to accommodate the thickness of the shower liner and allow the backer board to lay flat once installed over the liner. After you have reinstalled the backer board, make sure to reinforce the top seam of the cut backer board with the appropriate backer board tape and cover with thinset. You may need to trim the to-be-installed backer board pieces so the reinstalled backerboard bottom edge is gapped above the shower liner. Do not install the backer board directly on top of the shower liner as it can rub on the liner and create penetrations to the liner. Now when you pour your top mortar layer, the backer board will be incorporated into the mortar bed.

Once you have completed the above fix and the top mortar bed is complete, you could then apply a paint-on membrane product (like Redgard or Laticrete Hydroban) to the backer board walls, especially over the lower portion and carrying it up over the newly created seam. This should help prevent any issues with the lowish horizontal seam from patching the backer board.

Regarding the thickness of the mortar beds at the drain:

Hope this helps. Attach some photos if you like.

G

CDIY

Thank you for all the advice!

I’m removing the backer board around the bottom perimeter. I didn’t install blocking around the perimeter behind it, so this will also give a chance to do this and really get a *mostly* proper start, which will ultimately lead to a longer life for the shower (thanks to this site!). I also need to pull the drain and drill a larger hole and lower it an inch so it sits flush with the backer board. Now knowing I can go as thin as 1/4″ with the pre-slope at the drain means it time to modify the plumbing. Fortunately I have access from below.

To clarify, I didn’t pour the pre-slope yet but I did form and pour a very solid curb once the backer board was installed, so I have to cut and smooth around the curb to remove the backer board. I will then block the perimeter and pour my pre-slope right against the already-poured curb. FYI, for the shower floor I used 1/2″ backer board on top of the original 11/16 tongue & groove sub-floor, so it’s quite solid.

Question: For my pre-slope is the metal mesh/lathe all that imperative, as I’m not planning to carry the pre-slope concrete over the top of the pre-formed curb? I can’t staple it to anything since the floor is concrete backer board and the curb is already fiber-reinforced concrete.

Any additional advice you can give about the folds and/or cuts in the vinyl liner up and over the curb? Seems like it’s going to be tricky to make that work, and I don’t want to cut the liner excessively if I can avoid it. Does vinyl adhesive stick to concrete backer board?

Regards,

Adam

Hi Adam,

I think removing the lower backer board is a good plan.

Yes, in review I would:

I would also review these two excellent articles on shower pan construction:

Shower Floor by The Floor Elf

How to Build a Shower Pan by The Family Handyman

G

Hello,

I ordered the same drain assembly you used for this project, thinking it would have a pretty ornate metal face plate like the one shown in the closeups, but it does not! Can you please tell me where you got that nice face plate? I know it has been a few years since the original post, but thought it was worth a shot.

Thank you,

Joan

Hello Joan,

The drain is the Kohler K-9136-BN square design tile-in shower drain in brushed nickel. You can find it on Amazon. My drain does not have necessarily have an ornate design, but does have a very solid, clean appearance.

Gary

Don,

I wanted to add a bit more to your questions. I understand your drain questions and yes the pebbles (hopefully rounded) to not puncture the liner are still used. There isn’t much of a difference between this drain prep and a regular shower with a standard drain. You mentioned you would float the mortar up to the top surface of the linear drain after you slipped in place? You would be leaving room for tile yes?

Regarding mastics and thinset. I might first answer that question and say mastic is junk, but that would be terse and probably not true. Actually I love mastic because you don’t have to mix thinset and there is almost no waste.

Just don’t use in a wet environment unless it’s okay by the manufacturer and even still make sure it’s completely okay.

Good luck it sounds like you know how things work and are probably quite skilled.

Onga

Gary. Onga,

Hats off and many thanks for all of the great info and your time! Having taken the time to read all of the questions posted and your answers I do still have a couple of questions.

First, I would encourage folks to read down through all of the questions asked previously as there is a lot to learn and many of the same questions have been asked and answered many times.

That said, please forgive me if I missed seeing my questions that have been answered previously.

I plan to use a linear drain and the top edge of the drain (finished tile height) will be roughly two inches above the rough in drain. It’s a slip fit into the rough in drain. My question

/ concern is how this will impact my pebbles placed around the drain for the weep holes to function. They will be covered by nearly two inches of mortar. Can you point me to or provide some details on how to do this correctly?

The finished drain will be at the far end the shower (six feet) which is also furthest from my curb. So I will be installing a simple one direction slop albeit a long one. The drain is located about three inches from the opposing wall so my thought is to run my first pre slop to the the beginning of the drain flange but stop there.

Believe I have to do it this way so I can then install my liner, clamp it into the rough drain and then slip in the linear drain with the height adjustment feet carefully setting on the actual liner??? Then install my second and final mud bed and capture all of it while bringing it up to the finished edge of the linear drain.

I fully understand all of your previous guidance given and correct material layers/process.

Next, would you please provide your thoughts on using Mastic versus thin set for setting tile?

I’ve had great success using premixed Mastic in the past but may just be lucky to date. Seems to have better adhesions, especially on vertical and overhead applications and is much easier to use although a bit more expensive. I have used thin set in mostly floor applications where I needed to account for some small amounts of leveling when installing the tile.

Many thanks from the guy that says the more I know the more I realize I don’t know.

Sincerely and best regards!

Don in KC

Hi Don,

Thanks for the nice feedback and questions.

Let’s start with your last question first – mastic vs. thin-set. Thin-set mortar is mixture of Portland cement and sand (and additonal additives depending on the product) used as a tile adhesive. Thin-set mortar is intended for use in relatively thin beds of 3/16″ or less – hence the name. Because thin-set mortars are concrete products that cure water resistant, they are well suited for areas of high moisture exposure (showers, bathrooms, etc). Latex fortified or other “modified” thin-set mortars simply add a polymer (like latex) to the mortar for improved bonding, plasticity, flexibility and strength. These fortified thin-set mortars are excellent for applications requiring excellent bonding (shower walls, ceilings, etc), durability (exterior) and over more difficult substraits (plywood, etc). I used a latex fortified thin-set mortar for this shower install (Pro-Flex Platinum fortified thin-set mortar from The Tile Shop.

Mastic generally refers to liquefied organic adhesives that can be used to attach tile and other materials (think construction adhesive). But, because these compounds are organic, the tend to not stand up to wet environments and can support bacterial and mold grow. For these reasons, tile mastics should generally not be used in wet areas (bathrooms, outdoor, etc).

Regarding your shower design and linear drain, I would carefully read the install instructions from the manufacturer, since there are many different designs. That said, if you plan to have your drain location not against the wall, but close to it, you should typically have slope on both sides of the drain – that is one long slope from the far wall to the drain and a short slope from the near wall to the drain. Without knowing more about which linear drain you plan to use, it would be difficult to guide you on membrane install. Regarding protection of weep holes on the drain, the concept is to add a coarse material over the weep holes (like pea gravel or tile spacers) to keep mortar from directly filling in the weep holes. Even though the mortar will let moisture pass over time, keeping the weep holes mostly clear of mortar improves water flow through the weep holes into the drain. I would email the drain manufacturer if the install instructions are not perfectly clear.

Enjoy and good luck!

You explained this how to build a shower pan very well. I am about to finish mine. Thanks for sharing.

Hi Gary,

Thanks for the site. Really useful.

I’ve noticed that most of the cutaway graphics I’ve seen show the first layer of pre-slope packed beneath the lip of the drain flange, so that the flange sits flush with the first layer of pre-sloped mortar. Unfortunately, I installed my drain before seeing this, and have inset my drain flange flush with the subfloor. What should I do in this case? Can I run the pre-slope up to the edge of the drain, using just enough mortar at the edge of the drain to cover the metal lath? If I do this, then the edge of the pre-slope will be slightly higher than the drain flange. I’m not sure if this is a problem. Let me know what you think.

Thanks for the info! From all the various websites and blogs I have viewed, your method seems to include most of the best practices everyone seems to agree upon. There is one area where I am really having a tough time deciphering which is the “correct” method (if such a thing exists).

The issue is, do I embed the concrete wallboard within the top concrete layer, or do I lay the top concrete layer first, and then place my concrete wallboard just above that? I understand the argument of stability, as you are unable to screw the wallboard below the liner, but I have also read that this can cause the water to be “wicked” up the concrete wallboard. I know you have addressed this both in the tutorial and the comments, so sorry for the repetition. I guess my question is, what is the argument against laying the concrete wallboard above the top concrete layer of the shower pan? Thank you!

Hi Dom,

Thanks for the nice words and using the site.

Regarding the question of whether or not to embed the shower backer board into the top mortar layer of the shower pan, I would offer the following:

1. The concept of gapping installed panels above a flat surface is probably more relevant for water sensitive materials installed over areas with potential for standing water (plywood installed over a flat slab for example). A properly sloped shower pan should move water away from the walls and shower backer board should not be harmed by exposure to water.

2. Many of what I consider to be “expert” resources suggest embedding the backer board in the top mortar layer. Here is a great graphic courtesy of the excellent resource Fine Home Building: Shower pan cutaway from FIne Home Building Magazine

3. If you embed the backer board in the top mortar layer of your shower pan, remember to space it above the shower liner. This will help prevent mechanical damage to the shower line with any wall movement.

4. With a properly installed shower liner (installed well up the base of the shower wall, behind the tile backer board), any potential wicked water should be contained by the shower liner and not present a risk to the wall or shower structure.

5. Gapped panels may affect the stability of the backer board may adversly affect the installation and performance of shower tile.

So, in summary, I would embed the backer board.

Thanks for the question,

Gary

Afternoon Sir,

Thanks for the great tutorial. I have a few questions and need some assistance. I had my shower hot mop, sloped and tested. No leaks and tested with water for a few days before inspection. Do I need a metal lath to finish the mud deck and dam or to do without it? Please advise.

Afternoon Sir,

Thanks for the great tutorial. I have a few questions and need some assistance. I had my shower hot mop, sloped and tested. No leaks and tested with water for a few days before inspection. Do I need a metal lath to finish the mud deck and dam to do without it? Please advise.

Hi Tom,

I will answer you a bit and I am sure Gary will respond soon. If he is busy and doesn’t please feel free to ask more details. I will try and keep it short.

Yes to the wire or mesh. This acts as a re-bar to hold the mortar together. I use Mapei lath (plastic lath) over my waterproofing so their is no threat of compromising the vinyl or in your case hot mop. Make sure the hot mop didn’t block your drain weep holes (these need to be open).

when you do the metal lath on the curb you can use expandable metal (diamond lath). Just measure and cut it to fit, then fold it as if it was a glove that will slip over the shape of the curb. I use tape on any exposed edges so nothing sharp can puncture the liner.

If you don’t have experience floating then you can probably get away with doing a heavy skim coat over the entire curb and wire. DO NOT USE staples, screws or anything to puncture the waterproofing. After you cut and form the curb it should fit snug over the curb and with the mortar skim coat it will be held in place.

One last question: Is your wall paper over the hot mop? It looks as though it is, but just wanted to ask.

Good luck, Onga

Hi Gary,

This is a picture of the second mud pan of my shower. A thin top layer of the concrete crumble off. I’ve read through your post and understand that latex thinset mortar could help smooth out the surface of the mortar bed, after rolling on a layer of primer? Is that correct?

Thank for being so helpful to all of us diy-ers:)

Nga Phan

Hi Nga,

Sorry I am late getting back to you. Have you finished your project yet? If so, what did you do with the shower pan surface?

Looking at your photo, it’s clear that the shower pan surface is quite irregular and patchy. This surface would be hard to tile over and likely fairly unstable as it looks brittle. I would guess that your mortar was too dry and not completely packed when you applied it. If the surface is still in this condition, I would remove as much of it as I could and re-apply a uniform, properly-mixed mortar layer. Latex may help to strengthen the layer, especially if it is somewhat thin (it appears thin in the photo).

Another option may be to lightly tap the mortar with a hammer to loosen any brittle sections of the mortar and then apply a topping layer of a latex-fortified thin-set to create a smooth surface. Let this thin-set layer dry overnight and then apply tile. I would only do this if most of the top mortar layer is fairly solid and sound (it doesn’t appear very solid in your photo).

Sorry for the delay in getting back to you, I hope you found a suitable solution. Let us know what you did if you like, or if you have further concerns.

Gary

Gary,

I’ve read through most of your responses – and haven’t seen my issues. I’ll start with what I did; 3/4″ subfloor, relocated the shower drain, patched the hole, added 1/2″ plywood, tar paper, wire mesh, custom float needing mortar @1/4″per ft,[that was after the 1st attempt failed when I stepped on the pan and it cracked where the old drain was] liner, lastly – top mortar. That was ~ 3-months ago and as you can see from the photos – I have cracking yet again – along with ~ 1/8″ of vertical movement between the top layer and the liner. The shower is 66″L x 42″ wide, utilized (3) 2×4’s for my curb, and plan on having a bench 42″ w along back wall.[I believe I made a mistake here as well – as I didn’t frame it prior to the liner install and already glued the Durock to the back wall. My thought here is to sister additional 2×10’s to the joists below and adding cinder blocks for the bench. Please advise as to what you would do in this situation moving forward.

Kind Regards,

Garth

Hi Garth,

Thanks for the questions. Unfortunately, your images didn’t get uploaded (try it again using the “Choose File” button above the submit comment text block field), but I will try to answer your questions based on your explanation.

Regarding the separation between the shower liner and the top mortar layer, I suspect this will not be a significant issue. Depending on the size of the floor tile you plan to use, you should have no issues with installing tile in a thin set mortar bed over this retracted mortar. As long as the shower liner is intact and uninjured, I would move forward with the top tile layer.

Depending on the size of the gap between the retracted mortar and walls, you may want to fill the gap with thin set mortar and allow to dry prior to laying tile. Just be sure to not injury the shower liner when filling in with thin set. Use a soft tool to spread and level the thin set in the gap (like a grout float or a kitchen spatula) to avoid tearing or puncturing the shower liner.